Management of electrical materials at construction sites is not something to be taken lightly as lives are dependent on their safe use practices. Construction sites are prone to the hazards of accident resulting from equipment failures as well as human mistakes. Some of the most critical injuries and deaths result from electrical hazards. Here are the reasons to buy electrical safety equipment:

Regulatory Requirements

The US Department of Labor – Occupational Safety and Health Administration requires that employers provide employees with safe working conditions. It allows employees to file complaints, which will allow OSHA to inspect a workplace. The occupational Safety and Health Act of 1970 Standard practices and practical guidance policies are available, which apply to construction sites, demolition sites, and renovation work as well. There are legal implications in case of failure to use electrical safety equipment as your workers could file a complaint with the safety authorities.

Here are a few precautions you can take as an employer:

- Use industrial plugs for all handheld tools and electrical equipment at the construction site.

- Always examine cables before use and ones with frail insulation should be reinsulated or discarded.

- Have prescribed earthing systems installed at the site along with mobile generator, if necessary.

- Install distribution boards for the safe distribution of electricity in the required areas.

Audits and Inspections, Penalties and Fines

Understand the local, state, and federal product safety standards, certifications and maintenance requirements. Always be prepared for electrical safety inspections and audits by OSAH on a periodic basis and ensure that your electrical equipment and other construction equipment comply with the regulations. As per OSHA laws, non-compliance with regulations can result in penalties and fines, which will eventually drive up the overall costs.

Avoid Accidents

Serious accidents and deaths have been known to occur from the failure to use electrical safety equipment. To avoid any kind of unfortunate accidents at your work site, use electrical equipment, which is safe for use and suitable for the electric supply to which it is being connected. Do not try to use equipment with frayed wiring or insulation as this is not your house, but a construction site and one unprotected spark or a wrong wiring can lead to disastrous consequences for everyone at the site.

Avoid Financial Loss

The erroneous use of electrical equipment or plugs, cables etc. can result in fires and destruction of property and equipment at the site, leading to heavy financial loss and delay in project completion. If there is a fire or electrocution accident at the site resulting in the injury or death of a worker, the builder will have to pay for medical expenses and also deal with legal issues and government penalties. The resulting impact is multiple for the employers and the workers’ families, leading to several thousand dollars in compensation.

From the above, it is obvious that electrical equipment should be used prudently at a construction site to avoid financial loss and physical injury. The philosophy of “better safe than sorry” is applicable for construction companies using essential electrical equipment. Since one cannot avoid using them all, electrical wirings, equipment and gadgets have to be used with utmost caution and safety.

Electric connectors tend to be electromechanical connections helping to determine link and consequently transfer electric signals in between products. They can be temporary or even permanent. While the temporary types are proposed for portable tools with a tool employed for putting together and dismounting; permanent fittings help to sign up for electrically two discrete wires or even appliances.

Numerous characteristics determine the nature and particular purpose of the connector. Utilization of electrical connectors

Use of electric fittings

The actual connectors are utilized to link wired devices to establish the route for tranny associated with electrical signal via them. Their compatibility along with devices and sturdiness often safeguard the electrical signal from getting damaged because of exterior interference. A few connectors additionally are designed to shield you from hostile external factors for that wires connected inside them. All the connectors are customized produce to operate with varying degrees of current. This allows smooth working of the particular electric device that cannot directly draw power in the connection source supplied. The fittings regulate the present flow to really make it suitable for the mechanical structures from the products being connected via all of them.

Types of electrical fittings

Various types of explosion proof electrical connectors have been designed to execute a specific online connectivity purpose depending upon the situation. Notable included in this are being handled below:

Wire Fittings: Wire fittings serve to set up linkage in between multiple wires via a generally shared stage. Common good examples tend to be crimps, split secure, lugs and set anchoring screws. The actual plastic fittings wrap themselves around the cables in order to firmly safe the actual wires as well as safeguard the integrity associated with electrical sign transmission. Advanced fittings come designed with a square shaped spring internally that securely contain the cables by applying tension in it. Because the connector is actually stiffened, the actual spring sets by itself firmly round the wires.

The actual connector could be garbled around the cables by providing them removed to about fifty percent to 1 inches and becoming their finishes lined up. With regard to longevity and sign consolidation, the actual wires ought to be garbled along with pliers within clockwise mode. It will act as a safeguard against accidental loosening associated with cables in vibrations prone locations.

The fittings are available in varied colours using the colour representative of the wire dimension suitable for a specific connector.

Plugs and containers fittings: These types of fittings are mixture of male and female components that suit with each other comfortably. The male part is called plug and includes a number of prongs and hooks. This matches within style to the feminine equal called container, by which on attachment the matching connections securely latch themselves on.

The connect is a man cord installed cabling set up using the pins intended for performing electrical sign are subjected by having them protruding from the device. Plugs tend to be basically lifeless unless of course bringing them in touch with an electrical supply. The container is the feminine flange mounted wiring device having the conducting component recessed underneath the multiplying part. It’s reside ” cable ” even though there is nothing connected this.

Gateway connectors: EMT Conduit fittings function the larger purpose of redirecting several electric contacts via it to safeguard from outwardly sustained problems. The steaming program provides a router with regard to defining the shape of wires set up as it makes it’s method to a 4 way stop container.

The actual mechanised safety towards the linked wires is supplied by production the actual external layering from steel, fiber or even plastic. The actual agility as well as longevity of these materials are employed to varying levels to supply protection within varied environments.

Electrical wires are conducting media made of copper or aluminum and transmit electricity between many devices. They come in differing types and sizes to adequately manage the quantum of load and function in varied working conditions.

The different types of electrical wires are being dealt with here. The info will help you supply the right electrical wire for residence or even commercial establishment.

- Single-Conductor wires: All of these come in stranded and solid versions. Whereas the stranded ones finds application in electronic appliances for instance cell phone chargers owing to their flexibility; the solid ones find use in long and running wires due to rigidity and better conductivity. The most utilized types of single-conductor wires are thermoplastic high heat-resistant nylon-coated and also thermoplastic high water-resistant nylon-coated wires.

- Multi-conductor wires: This kind of wire cables are concealed underneath walls as well as serves electricity to high load appliances for example washing machines. A plastic sheath encases live, ground and neutral wires. They are made to work with appliances with 120/140 circuit rating.

- Metal-clad wires: A spiral aluminum casing encloses the live, ground and neutral elements forming the wire. It can withstand heavy loads with the metal casing built to act as safeguard against wire failure and so fire hazards; and as such it is recommended for industrial use. It is highly expensive.

- Metal and insulated cables: A thin metal rod threaded with small, thin strands is used. The metal is chosen based on its weight, conductivity, strength, melting point, and also ductility. Insulated wires are found in heavy electrical equipment and automobile sector prominently and even are encased in plastic or rubber sheath.

- Braided and fuse wires: Braided wires are made by interweaving of individual conductor wires. This serves to lower the wear when electricity is transmitted through the wire. Fuse wires are for connecting fuses to facilitate current flow. Metals used are aluminum, nickel, chromium or iron. The wires melt under high electricity flow to guard the devices being connected from getting damaged.

- Shielded and Thermocouple Wires: Shielded wires are externally guarded with a covering and is made up of few layers of conductive wires and insulated layering. A shield layer safeguards the insulation layer from internal wire. A composite tape layer wraps itself around insulated wires. Heavy industry uses them. Thermocouple wire, for example duplex insulated wire is used to detect heat variants.

- Thermostat, Winding, Armoring Wires: Thermostat wire finds application in temperature regulating devices. The low voltage control wires are normally made out of PVC insulated uncovered copper conductor. Winding wires are ultra-low resistance copper wires utilized in electromagnetic devices. Armored wires feature an interior cable wrapped with strong steel strands and even are heavily insulated. They have 3 layers of sheathed cover and also have application in underground or high wear regions.

- Coaxial, Enameled, Hook-Up Wires: Coaxial cables utilized for telecommunications sector feature round conductive sheath covering an insulating spacer over large round center copper wire. Enameled wires applied for powering motors feature enameled coated copper wires. Hook-up wires manufactured from copper and aluminum find application in low-voltage devices and the constituting wires are not insulated in regard to each other.

- Single-core wire: It is used for connecting low-voltage light appliances such as string lights wired in a sequence.

- Dual-core wire: This wire is utilized for connecting low-ampere circuits like home lamps to power source when ground wire is not required. It features two color coded interior wires as well as an external coating. Neutral wire is marked with white or gray, while positive wire is marked with black or orange.

- Tri-core wire: It connects electrical devices that consume higher amperes. Mostly utilized for domestic purposes, the AWG rating varies from 16 to 8 based on ampere rating of device. It features 3-color interior wires plus nonmetallic external coating. Ground wire is green, neutral is gray or white and positive is red or orange.

Wire Size

Required wire dimension could be safely calculated through measuring the existing distance between power source and the appliance being wired then doubling the reading. This figure is to be tallied with the electrical appliance’s ampere rating and the AWG (American Wire Gauge) table is to be known as arrive on the precise wire size. AWG uses a intricate numbering pattern ranging from 40 to 0000, wherein 40 indicates the thinnest and 0000 refers to the thickest wire size. 40 are for circuit board application and 0000 for heavy duty industrial use. Commonly used wire gauges are 16 (lamps), and 8 (electric stoves and central heating units).

With so many different kinds of commercial lighting fixtures available, it could be mind-boggling to choose the right electric fixture for your home or office. However, in case you know the different forms of lighting and what they are best suitable for, you’ll be able to opt for the best electrical lighting products to illuminate your home or even workplace while also saving energy.

Varieties of electric lighting products

Electric lights are available in many formats. You can choose the one according to your needs and preferences.

Recessed Lighting

As the name suggests, recessed lighting is installed into an opening which is flushed with the ceiling. There should be a minimum of 6 inches gap between the roof and ceiling for fitting of recessed lighting. Also, there must be insulation to prevent condensation from making its way into the fixtures. Recessed lighting can be used as accent lighting, task lighting or simply ambient lighting. Recessed lighting are normally utilized in kitchen, covered patios, hallways and so theater rooms, where you never want the light source to be visible or maybe where there is limited overhead clearance. You can use incandescent, halogen, LED and low-voltage halogen bulbs for your recessed lighting needs.

LED Lighting

LED or light emitting diode lighting is fast replacing incandescent lighting in commercial spaces and also homes. Unlike incandescent bulbs, LED lighting is quite energy efficient. This lighting was invented in the 1920s in Russia and made its way to the United States in the 1960s. They are long lasting plus can last for around 50,000 hours of use when they are lighted utilizing 70 percent of their original power. Compared with traditional lights, LEDs do not flicker or even burn out. Instead they basically fade when they are nearing the end of their lifespan.

Track Lighting

Track lighting refers to a series of lights used to illuminate a space. Normally track lighting uses electrical wiring encased within a plastic or aluminum track, that can be connected to already existing circuits or even be plugged into the wall socket. Track lights can be mounted on a wall or simply ceiling after which separate lighting sockets can be fixed into place along the size of the track. Track lights is outstanding for highlighting design elements or maybe special features, with each light fixture pointing in a different direction. Utilizing track lighting, a commercial space can hang spotlights and floodlights unobtrusively from the ceiling. At your house, these are typically found in living rooms and dining rooms where you need to highlight a section of the room.

Wall Lighting

Wall lighting normally include track lighting, wall lamps plus recessed lighting. In most cases wall lighting helps to enrich the d’cor of a room. It is used to save floor space while fulfilling the lighting needs in a room. Exterior wall lighting can be used to illuminate doorways and paths and to illuminate dark areas surrounding an office building. Many wall lighting are available to suit a room’s d’cor whereas ensuring that plenty of light is available for work-related activities.

Mini Lights

Often mini lighting refer to vacation lights, which people use to decorate Christmas trees, homes and business establishments. These kind of lights can be utilized not merely during holidays and festive occasions, however also all year round to add charm and sparkle to a home or maybe a commercial establishment. They are available in several colors and so are really flexible, as they can be draped or even hung to give an uplifting look to the space.

Outdoor Lighting Fixtures

Any commercial establishment and also homes will need outdoor lighting fixtures, which are normally used for safety, security as well as guidance. There are several types of outdoor lighting fixtures, with retrofit lighting offering reduced energy consumption and even money saving in the long-run, as well as outdoor post lighting, which offers an economical way to illuminate large areas, being the most popular. You need to think about the reason you will need outdoor lighting and then select fixtures accordingly.For more information about electrical wires and cables visit our web site.

Purchasing electrical boxes is not easy as you must take into account many parameters for example material, shape and measurement of the box, where and how you’re going to set up the box and how will you protect it. If you’re about to source electrical boxes and finding yourself with a lack of knowledge, this article can be of help since it details everything necessary regarding electrical boxes to assist you make the right choice.

About Electrical Boxes

Electrical boxes systematically encase the wires which is often connecting applications like switches, electrical fixtures etc to major power source. Boxes are available in a diverse range for addressing different type of needs of internal, external, wall mounted and application oriented wires.

Some other uses of electrical boxes are:

- Streamlining periodic maintenance and even up-gradation activities of electrical components by means of easing access to these.

- Substantially reduce chance of fiery incidents and also short circuits by adequately grounding electricity conducting wires.

The nature of electrical boxes and even corresponding installment procedures for dedicated applications are governed by The National Electrical Code and regional building regulations. The code cautions towards covering the boxes with paneling, drywall or other wall embellishments. A uniformity of cover design is to be implemented all over all boxes. The code stipulations plus requisite permits can be learnt from local development inspector. After installing electrical connections through boxes, it is best to get the same inspected to concentrate on compliance and safety discrepancies.

The important considerations which have to be counted in right before purchasing right electrical boxes are:

Electrical Box Types

Handy box: Recommended for accommodating light receptacles plus switches, this wall surface mounted box comes handy in areas where installing beneath the wall is tough.

Junction Box: It facilitates interconnection of wires allowing for secure splitting of circuits and ramification in various directions.

New-work box: This sort of boxes get installed during preliminary work of a new building. Stud or simply joist mounted, the box is quite often fitted in midst of studs with a bar hanger previous to applying drywall.

Old-work box: This type of boxes are set up post drywall application and offers additional electrical outlets. Clamps inherent in the box enable hanging on the drywall.

Outdoor box: The boxes comes in metallic and also non-metallic units as well as give protection to wires from hostile weather conditions through sealed seams, watertight covers and gaskets.

Box Material

Electrical box is built of metals for example cast iron and aluminum or non-metals like plastic or PVC. Metal boxes last long and even make sure steady performance also under adverse conditions. They are to be utilized for exposed indoor applications just like conduits, in areas where construction is in progress.

PVC or plastic box is comparatively less costly and so give hassle free installing in both new and also old work situations. This sort of boxes should be just utilized with non-metallic wiring.

Box Dimensions

The box best suited to your requirements really should be scanned totally based on needed shape and size.

Regular rectangular box is used for encasing single electrical outlet or even switch. Square box is utilized for accommodating 2 devices, i.e. outlet and switch combined or even a pair of either of them. Octagonal box is deployed for enclosing lightweight fixtures or ceiling fitted smoke alarms or varied detectors. Ceiling box is built for holding heavier fixtures for example chandeliers and fans.

Box Features

Box Cover: Interior electrical box cover should be simple or can don decorations to add glamour to home d’cor. Exterior covers ought to be watertight. In-use cover must be used for outlets that provides for whole coverage actually in the event of a device being plugged in. Electrical junction box cover is plain as well as serves the double purpose of concealing the wiring as well as enabling easy accessibility.

Braces and bar hangers: They’re attached in midst of joists allowing for positioning of electrical devices in multiple places. They enable ease of positioning with minimum damage to ceiling.

Extension rings: They are utilized to deepen the electrical box adding extra space to hold additional wires.

Adjustable depth boxes: They facilitate the electrical box to sit flush with wall surface area irrespective of wall material’s inherent depth.

Some key set up tips

- Installing of electrical boxes in new construction should essentially beging with mapping the place to allow for sufficient number of boxes to hold all fixtures and devices.

- A stud finder is to be deployed for stud location in finished regions. Ample steps should be taken to prevent them from impeding new box placement.

- Rough box outline has to be traced on the wall to facilitate marking cutting lines. For drywall, use utility knives; for plaster, use keyhole saws as well as wood, use saber saws.

- A minimum distance of 42 inches from the floor is to be maintained for light switch installation; whereas for power outlets, the gap should be 12 in ..

- The complete array of wires ought to be thoroughly labeled for allowing future alters.

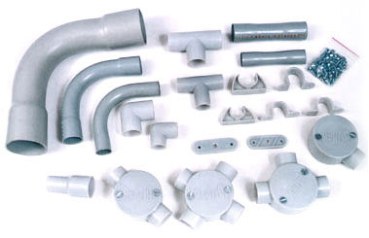

What exactly is an electrical conduit? It is the electric accessory that protects and conceals electrical wiring. It is usually a hollow pipe which might be made from various materials. Most often, electrical conduits are extremely simple to install. The way you mount electrical conduits relies upon the material they’re made of and also the installation layout. Your expertise and experience in the area will also play a major role in how efficiently you can do the mounting.

Electrical conduits keep home look clean and or even donate. They furthermore shield the wires so that you can enjoy years of good service. Though setting up electrical conduits is not rocket science, you might have to hire a professional if you’re doing it for the first time or if the structure is too complex. For less complex installations, below are some tips to help you perfectly install your electrical conduits:

1. Meticulously Choose the Type of Electrical Conduit

Selecting the material of the electrical conduit is not a difficult activity. For simpler layouts, you should use the most common and most inexpensive electrical conduits that are made from PVC. The PVC electrical conduits are an easy material to use; yet, they are doing have a disadvantage: they cannot be bent. For bends, it is advisable to use prefabricated elbows.

Metal conduits are another kind of electrical conduits that you can use. They’ve got their benefits as they give much better security and even are elastic. Yet, they’re not as simple to handle in terms of installation as PVC conduits. For starters, they might pose a real challenge. In terms of EMT conduit fittings or simply electrical metal tubing, these types of electrical conduits are really simple to work with as they give you both high protection and furthermore much better flexibility.

1. Don’t Complicate Your Layout: Make it simple and Straight

Electrical wiring works best when the conduits are kept as straight as possible. Since you must be well aware of, it is actually difficult to make it all a straight line. The thing you could do is to reduce bends and elaborate layouts as much as possible. This simple layout will not just let a much better service of the electrical wiring, but it will additionally protect you from troubles down the road when you will need to pull the wires.

2. Cut Electrical Conduits: Use the Right Tools at the Right Angle

However you will think cutting is not something you ought to worry about, there are lots of problems with cutting electrical conduits. Problems are usually related to the tools used as well as improper dimensions. Depending on the type of material used, you have to use a different tool. PVC conduits are to be cut with a hacksaw. A tubing cutter is best however. For metal conduits, a hacksaw will work excellent while a pipe cutter works even much better. Also, always measure before you cut and always cut at a 90° angle.

3. Pulling Electrical Wires: Be Smart

Electrical wiring will have to run through the electrical conduits. That is the way things work. Sometimes, you could install electrical conduits on the electrical wiring but sometimes you can’t do this. You ought to pull the explosion proof electrical wires through the electrical conduits. In these instances, your very best shot is to use fish tape to pull the cables. This way you will not damage the conduit or the wires. It is easy to use: run fish tape through the electrical conduits, affix the wires at one end and pull the fish tape at the other end.

As you can see, installing electrical conduit is not so hard so long as you remember these very simple tips. When it comes to intricate arrangements, it is always much better leaving them in the expert hands of the experts. Once appropriately chosen and accurately set up, electrical conduit and conduit fittings are a safety requirement.

As a do-it-yourself (DIY) person can be very advantageous particularly where costs are concerned. By simply attaining certain things by yourself, you actually reduce labor expenses. This certainly leads to lower overall expenses when undertaking any project. One such endeavor you can undertake on your own is to set a conduit body, mainly when designing a new house or setting up an extension.

Functionality

Conduits are basically tubular devices built to be placed on walls. It’s through them that service wires pass to different areas in a building. You’ll most definitely find electricians rely on them when wiring a building.

One of the key features of conduits is that they will let you quickly access wire cables designed to serve different rooms. You just insert the needed cables into the inlet and press the same until the wires reach the outlet point, that can be a junction box or simply a switch. Conduits likewise serve to offer protection to cables within from unwanted damage.

Materials

Something you seriously have to note is the fact that conduits are made of various materials. It is therefore really important that you think about the reason for installing the same so that you will only get the best suited one in relation to material used. You will probably come across conduits made of aluminum, galvanized steel and PVC. All these different electrical materials are perfect for use in different environments.

Types of conduits

Apart from the materials used in making conduits, you are as well obligated to just get a type that best suits your wiring needs. Note that the different types as well serve different functions. The truth however is you will have to purchase different types of conduits so that you will effectively wire your building perfectly.

* L-Shaped – This is the most common types of conduits available. You’ll require an L-shaped conduit if wiring your building involves passing wires at tight angles such as 90-degree angles. The L-shape lets you easily direct wires through to the required location on the wall.

* T-Shaped – This is one of the most crucial type of conduits you will possibly not do without when wiring a building. It’s importance lies in the fact that it allows you to easily route wires in three different directions. It’s easy to use it to route 3 different wires; one down the wall, one to the left and the other toward the right.

* C-Shaped – Even though commonly known to as C-shaped cables, this type is usually straight. It is probably the most common types of conduits you will find. You will obviously need this type because of the need to pull wire cables over a long and straight wall.

Conduits are generally designed with access covers at the inlet that you can easily remove. Depending on the functionality, you may have to change the covers after wiring. It is very important mention that the above are not the only types of conduits you are likely to come across. I have listed the most common that are commonly used in houses. There are also industrial conduits service like conduits that some home owners are now getting plus using at home.

Today, all buildings should have circuit breakers on the power boards. They act like the old designed fuses however they can be switched on and off. When a fuse “blew” you had to change the entire fuse or just at the very least the fuse wire. A circuit breaker takes the place of the fuse. The fuses were there as a safety safety measure between the electricity coming into the house plus the appliances at home. A circuit breaker is a much more convenient product because it makes use of metal strips that touch when power is passing through and pull apart when switched off.

What is a circuit breaker?

A circuit breaker is a piece of equipment that cuts off the electricity supply when a massive amount of power flows through the circuit. The current is linked through the appliance when it is turned on. Most appliances run at lower levels of current so when a higher level is detected the circuit breaker cuts the current and the appliance is powered down. The operating of the circuit breaker is like the fuse, when too much power goes through, it overloads and turns off.

How it works?

The circuit breaker sits at the end of electrical wires coming into your home and can be switched on and off. When powered down there isn’t any supply of power to your house. When the circuit breaker is switched on, power passes through the breaker. The circuit breaker works as a safety electrical product as well as has considerably reduced the number of fire caused by electrical appliances.

Why should you have circuit breakers

A circuit breaker is designed to eliminate a source of fire when an appliance draws a lot of power. Over the past numerous houses have been burnt down by faulty home appliances. The circuit breaker trip the power from the electrical wires that enter the back of the power box and go through the circuit breaker and into your house to power points and light switches.

This is a life saving safety electrical product that cuts any type of power to an device. When you switch the device on and it is faulty the circuit breaker will split the stream of electricity simply by switching off in a micro second.

The working of the circuit breaker helps you turn the power off to elements of the house when an electrician is working. You don’t need to cut the power to the complete house. In the past a fuse would be taken off it’s holder or the main power switch turned off. The fuse wire that’s used in fuses was quite brittle plus the slightest bump might lead to it to break, especially if the wire in the fuse was old.

How many?

All large electrical equipment such as air conditioners, electric ranges and Jacuzzis will have their own circuit breaker installed.

Many houses will have a couple of circuit breakers for power points and lights so not all of the house will lose power when a breaker turns off.

Circuit breakers work on a simple method which is an incredible example of an appliance which does big work. Circuit breakers have turn out to be an important part of our functioning day in and day out, making life less complicated in a lot of aspects. Above all, they make life safer for all of us and everyone in our environment.

Wires and also cables are part of all sorts of electric appliances. Naturally, there’ll be far more wires as well as cables lying around if you’ve got a lot of appliances in your home or place of work. You cannot ignore any electrical product as each has its own specific role. Just what you can do is arrange those cables to be sure cleanliness and also safety of your home or office place. People can trip on those wires and cables, hence it is important that they are as far from human contact as possible.

Managing outdoor cables involve several things. By making use of some special materials and furthermore following specific procedures safety at home and so in the workplace can be guaranteed.

– Nicely tie wires and cables – It is usually a bad idea to throw away the wire ties that come with the appliances. Once the wires are linked to their respective appliances, you can bundle all of them together using their ties. In order for the cables and wires to be less visible, ensure the appliances are as close to the wall as possible. Your home or maybe office decor would as well be maintained with this type of setup.

– Utilize the base boards – Loosely spread out cables and wires can be tidied by running them on the base boards. Base panels keep wires tidy and even provide a secure place to hold the wires together.

– Buy split wire loom – Split wire loom is a material which could both, protect plus arrange wire cables. Another name for this substance is complicated lines. This material is primarily made of polyurethane. It has a split on one end where one can push the cables as well as wires. The split holds the wires and cables and in case you need to add a new wire, you can insert it without removing the whole bundle.

– Make use of wire snake cable organizer – This is an organizer that looks like a spiral wire. The snake cable is wrapped around the bundles of wire and commonly comes in different colors. This is helpful if you wish to compact wires into separate mini-bundles.

– Clamp cables with a cable clamp – It is another common organizer for cables and so wires. The cable clamp hold larger bundles of wires and so can be opened up or even closed in a handy way. This makes the cable clamp much easier to use compared to other materials. This organizer is a durable coordinator that can be used repetitively.

– Make use of cable zippers – The cable chords can be handled even more successfully using a cable zipper. It is an organizer that has two open ends. Wires would enter from one end and exit from the other. This will make cable zippers ideal for wires that track to a wall switch. Having a neatness and classical colors, cable zippers are ideal for greatly designed rooms.

All of the above can be used individually or maybe in combination with 1 another to keep your home and even place of work nice, tidy and arranged. Keeping the wires and cables hidden away will not simply help make your surroundings tidy as well as esthetically pleasing, although will additionally ensure safety for everyone around.

An electrical box is sort of a junction where exactly all of the electrical wires which link many electrical devices in a room culminate into switches. These switches serve as an interface for user to operate the electrical equipments, are preset in to the electrical box. Various types of electric boxes are found today for particular needs. Whilst a normal electric box could possibly be enough for a home, an explosion proof electric box is just what exactly you will need for a unsafe site. This post makes it possible to recognize the necessity for different kinds of electrical materials, especially electric boxes.

An electrical box is sort of a junction where exactly all of the electrical wires which link many electrical devices in a room culminate into switches. These switches serve as an interface for user to operate the electrical equipments, are preset in to the electrical box. Various types of electric boxes are found today for particular needs. Whilst a normal electric box could possibly be enough for a home, an explosion proof electric box is just what exactly you will need for a unsafe site. This post makes it possible to recognize the necessity for different kinds of electrical materials, especially electric boxes.

Different kinds of electrical boxes

Electrical boxes may be set up indoors or outdoors. They come in numerous styles, size and material based on the usage. Normally for indoor application like in your house, these electrical boxes are hidden in the wall, whilst in case of outdoor applications, electrical boxes have to be weather proof and moreover durable enough to guard the switches fitted within from any mechanical stress. The design of the electrical box is mostly rectangle, square, octagonal, or maybe round and are manufactured from either metallic (cast iron, aluminum, steel) or even non-metallic material (plastic, PVC). Plastic or even PVC boxes are low-cost and also easy-to-install however must not be used where metallic cables are used.

Difference between regular electric box and explosion proof electric box

Electrical boxes are important not merely from the aesthetic perspective yet likewise from the security viewpoint. Since these help in covering the electrical wires and additionally protect the users from any possible sparks that could possibly take place due to overload, loose connections or even ingress of foreign particles for instance dust.

Oftentimes these electrical boxes additionally will need to be installed in conditions which can be unsafe and hence they might should be designed in a different way from normal electrical boxes to make them explosion proof. A dangerous location generally entails an atmosphere where flammable or even explosive gases, liquids, or maybe dusts are present possibly all the time or when there is a failure in normal functions.

A typical electrical box which is to be set up in a non-hazardous location has to be just powerful enough to bear the weight of the enclosures and moreover provide safety to personnel towards minor sparks, that could occur because of loose connections or overburden and also give protection against the ingress of dirt / water Or oil and even corrosion.

Although, in case there is an explosion proof electrical box, you need to be sure security of the people, even in the case of a heavy explosion and that is why really should be bigger and also heavier compared to normal enclosures. The joints and also flanges of explosion proof enclosures will need to ensure that hot gases that are formed as a result of an inner explosion are cooled down to a temperature point that if they’re released doesn’t have plenty of heat to trigger another explosion. Depending upon the amount of risk to safety the design of the explosion proof enclosure is further calibrated. Explosion proof enclosures are produced utilizing material having high durability such as polyester, aluminum, and even stainless steel to ensure that in case of an explosion, there’s no external damage.

So now, that you have realized the significance of several types of electric boxes, keep the info in mind when souring electrical engineering materials.